Eggs need gentle handling and proper care to preserve its quality. At Hybrid Agrobots Pvt. Ltd., our primary objective is to avoid any kind of damages to the eggs, no matter how big or small it is. Our Egg Collection System is designed with automatic features to collect eggs on the poultry farms. To be more precise, our system is has a critical role to play in successful breeder and layer management.

We take care of every step involved in the egg collection systems – Transportation of eggs, good handling, and high functional reliability.

We designed the egg collection technique by implementing innovative technology and using state-of-the-art machine to ensure several benefits. These include:

Minimizing labour costs and time

Reducing damages to eggs and ensuring cleaner eggs and fewer cracks

Maintaining optimum egg quality

Maintaining a precise count of eggs produced per house, tier, or row in the poultry farm

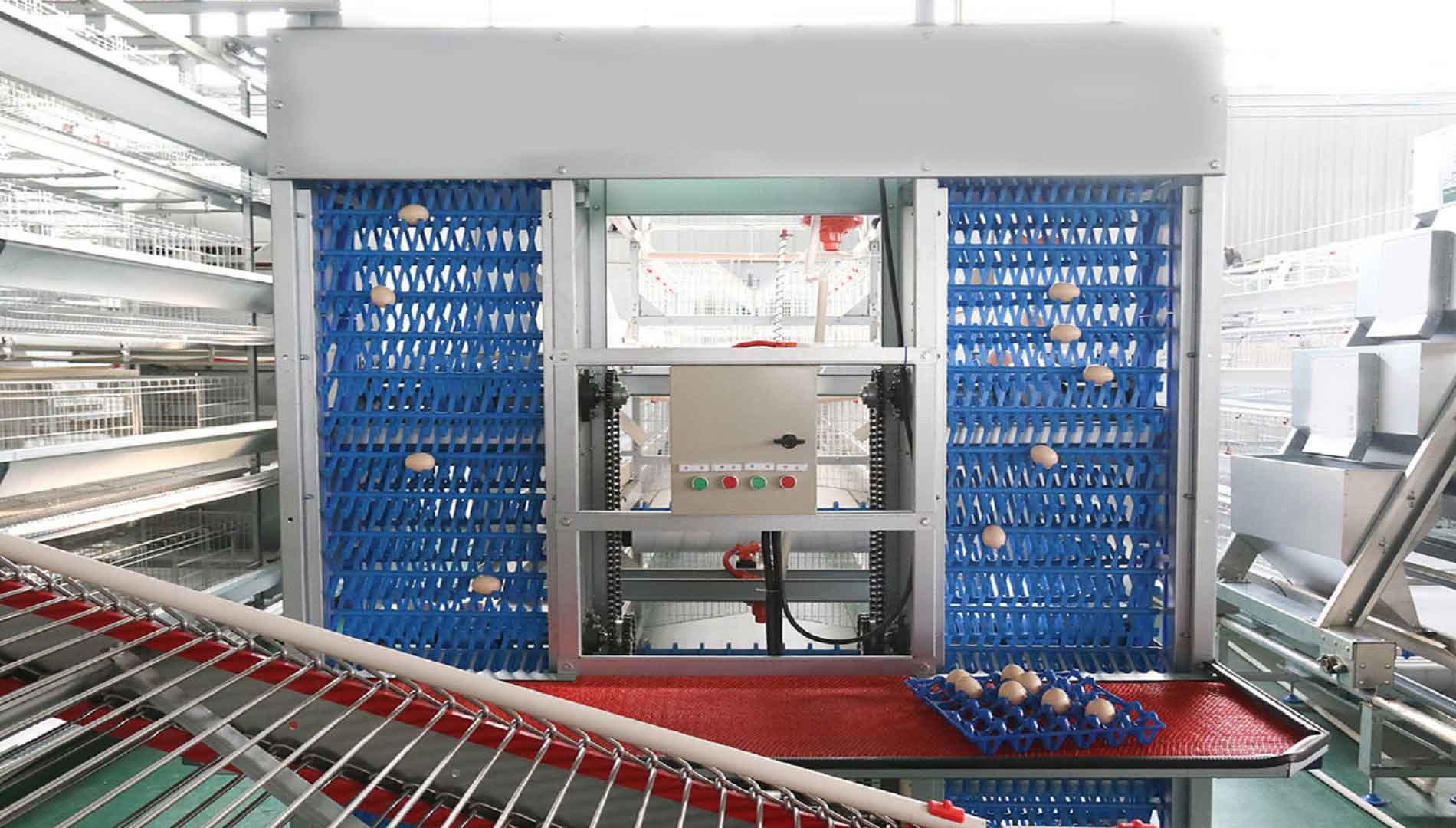

We have a professional and experienced team at Hybridagrobots who are aware of the best standards of requirements at the Egg Collection System. The system incorporates a range of various sections that include lift systems and ST elevator, sorting/grading machine, and so on.

The process of egg transfer demands proper scrutiny, sensitive handling, and smart management of transporting eggs. Our ST Egg Elevator in the Egg Collection System is ideal for proper egg transport and short systems without causing any damage to the eggs. The idea behind applying a specific pattern for egg transfer is to make sure that they are not mistakenly transported onto the already occupied steps.

Suppose poultry farm houses birds of various age groups. Our ST Elevator can be effectively used for the collection of eggs systematically, i.e., per flock or per row. We recommend setting the egg belts and elevator chains in motion separately so as to match the conveying capacity and the laying performance of the eggs as collected.

The dosing wheels have a significant role in the ST Elevator. The wheels aid in transferring the eggs onto the elevator chain. Next, the eggs are shifted to the lower sliding grille. At this point, the direction of the eggs are turned upwards to a desired height to move them onto the cross belt.

Make a note of this. The transfer of eggs can be of any desired height that depends on how the eggs are transferred – automatically or manually. The standard height is 2.10 m (Q 210) that guarantees a clearance height of 1.95 m. If the eggs are to be transferred manually, then the standard height is maintained at 80 cm (Q 80).

The Egg Collection section has the compact construction and it implements smart technology to ensure a large egg collection capacity. The idea is to follow the standard accuracy without causing any damage to the egg during the collection procedure.

Elevator System: The machine enables a large egg collection capacity and quick access to different flocks in separate cage rows in the barn. When it comes to safe egg transport and short systems, the Elevator System is the one to look out for. Egg belts and elevator chains are used to match the conveying capacity and the laying performance.

Compact sorting equipped with cam gear structure: The conveyor belt features a mechanical weighing system that allows grading of eggs. It helps to grade the eggs in sequence.

Light inspection and sorting accuracy: Eggs are best verified with the use of light. Light inspection process enables in the sorting of eggs for separating qualified eggs from the unqualified ones. Eggs that are yellowish in colour from the outside, have cracks on their shells, or any kind of other defects are rejected from the lot.

Innovative technology: Automated technology plays a key role in the egg collection procedure. AI-enabled modern vision system helps to find and classify the damages of the eggs.

Structure: The Egg Collection System is compact in size making it easy to utilize any storage space optimally.

When the eggs are lifted and transferred, they tend to get cracked or damaged since the exterior shells are extremely sensitive. The plastic core on the doing wheels in the Egg Collection System features a flexible and soft lip. The idea is to safeguard the eggs and prevent any hairline cracks during the transferring process.

The elevator chain is guarded with safety braces that are made of plastic. The material makes it light and flexible for the eggs and ensures they are safely transferred without any damages to them.

The ST Elevator and the Lift System jointly work to ensure the transfer of egg safely to its required destination. The eggs are collected per tier smoothly through conveyor that swiftly moves the eggs to the individual tier. Once the eggs are transferred to the tier, they are gently shifted to the parking position.

Optimal storage space

Uninterrupted access to all the tiers

Economical for small units or barns

Gentle egg transfer from the longitudinal belt to the cross belt

Hassle-free single egg transfer

The structure is bigger than the ST Egg Elevator since it comprises of three levels. The capacity the total volume of eggs is huge. It features an adjacent extra wide elevator chain that efficiently manages the egg collection procedure. So, what is the most significant factors of the EC Egg Elevator? It can collect up to 15,000 eggs per hour. The belts run parallel to the elevator thus, transferring the eggs in a systematic chain.

Huge egg collection capacity

Minimum storage space